Research & Development

Cleaning chemistry pioneer

Every day at Caramba, 20 scientists and experts in three research labs strive to provide you with the optimal chemistry. They develop top products in touch with your needs and tailored to your work processes. Tried-and-tested recipes for success are regularly reviewed to make them even more powerful.

Whether this succeeds is determined by a wide variety of test methods according to the latest scientific findings and tested by independent test institutions. Only the best recipes that have been put through their paces make it to production and to your company. There they unfold their full potential – with brilliant results, shorter application times and safe handling. This is how we offer you sustainable and economical solutions tailored to your individual requirements.

Test procedures

Mobile surface analyser (MSA)

Determination of the surface energy

Surface energy is crucial for many processes. In car wash facilities, the surface energy is deliberately reduced to optimise the run-off characteristics of water on washed cars so that no traces of water remain on the paint. However, when metal parts are cleaned in industrial parts cleaning, it is of crucial importance to obtain parts that are as clean as possible with a high surface energy so that subsequent processes are not disrupted. With the mobile surface analyser, we can determine the surface energy and optimise processes at the customer’s site.

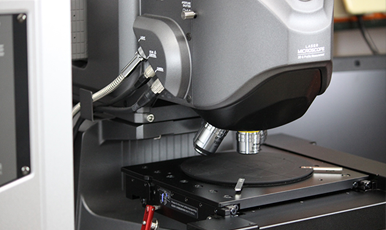

Laser scanning microscope

Determination of materials without contact

Whether this is for cleaning, coating or surface treatment, the exact surface properties and structures are crucial and must be studied carefully. With a laser scanning microscope, structures, roughness and layer thicknesses of a wide variety of materials can be determined without contact. A focused laser beam scans the surface and achieves an extreme depth of focus so that even the tiniest structures on the surface can be visualised.

Four-ball testing device (FBT)

Limit loads for lubricants

This method according to DIN 51350 is used to measure the lubricating properties of a material under high pressure (FBT value) The device consists of a running ball rotating on three lubricated stationary balls.

The test force of the running ball pressing on the stationary balls is increased incrementally. The FBT value is reached when the lubricant film breaks and the balls fuse through friction heat. In particular, the special lubricants from Caramba show top results with wear protection:

- Caramba Multiöl Super Plus: 2.200 N

- Caramba Hochleistungs-Schmierfett mit PTFE: 2.400 N

- Caramba Hochleistungs-Ketten-Spray: 1.900 N

Salt spray chamber

Maritime climate in the test chamber

The salt spray test according to EN ISO 9227 simulates an artificial maritime climate. Rust protection agents are sprayed here on metal surfaces under extremely corrosion-promoting conditions. Within a few days, it is possible to study processes, which would otherwise take months or years.

Standardised steel sheets are positioned in the test chamber at an angle of 45° and sprayed with water vapour-salt spray. The temperature is a constant tropical 35°C.

Under laboratory conditions, the percentage area of the surface that corrodes within a certain period of time is recorded precisely. Exact comparisons of different recipes and agents are thereby possible. The multi-oils and lubricants from Caramba protect especially effectively and in a long-lasting way against rust. The premium multi-oil Super Plus surpasses all competitor products:

- Caramba Multi-oil Super Plus: 5% corrosion after 14 hours

Windscreen cleaner test station

Test bench for a clear view

A clear view contributes to road safety. A windscreen cleaner must therefore be able to reliably remove dirt, lubricant films and rubber abrasion of the wipers. At the same time, it should care for the wiper blades and keep them smooth. Caramba therefore regularly tests its own windscreen cleaners in parallel with competitor products.

A windscreen with wiper and washing system is installed in the standardised test system with refrigerating chamber. The windscreen is prepared with test dirt – a stubborn mix of hot wax, silicone, soot and oil.

A camera records the cleaning process from the driver’s perspective and the effect is analysed electronically. In addition, Caramba tests the paint and plastic compatibility of the cleaner. The active ingredients for the care of the wiper blades and nozzles are also tested.

Our test procedures for wash chemicals

Test for product temperature stability

Determination of the clear melting point

To determine the clear melting point, product samples are taken and then frozen. It may take longer for the sample to thaw compared to pure water. In this way, the cold stability of the product samples is tested.

Abrasion and washability tester

Wipe test for quality testing of manual pre-washes

The abrasion and washability tester is a standard method for determining the cleaning performance of products. The test is carried out using standard sponges and with specially designed Caramba test dirt on a tile.

Measurement of the foam number

Testing the product foaming behaviour

To determine the product foaming behaviour, a 0.25 to 1% solution is whipped with a foam whisk in a graduated cylinder. The whipped foam column is determined in cm.

pH value adjustment

Determination of the pH value by titration

The pH of the product is adjusted and tested in this test procedure. Furthermore, the buffer capacity of the ingredients is checked and the product recipe undergoes quality control. The measured values indicate the strength of the cleaner.

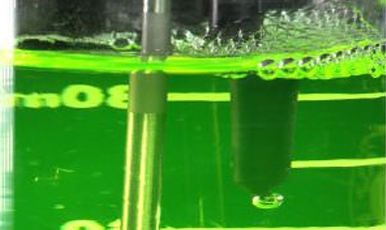

Bubble pressure tensiometer

Determination of the surface tension of the cleaning agent

An air bubble is generated in the cleaning agent as a function of time. Over time, the entire surface of the air bubble is enriched with surfactants, which lowers the surface tension.

Less energy is needed to generate the bubble when it is completely wetted with surfactants than if no or fewer surfactants are on the surface. The required force is recorded as a function of the velocity of bubble formation. This allows the velocity and wetting behaviour of a system to be determined.

Analysis of the runoff

Runoff of a liquid droplet on a standardised paint surface

The paint surface is treated by spraying with or dipping into a water-repellent agent (a chemical drying aid, wax or impregnation). By treating with the product, the paint surface becomes water repellent.

As a result, the velocity and residual moisture can be determined to highlight the quality of the product.

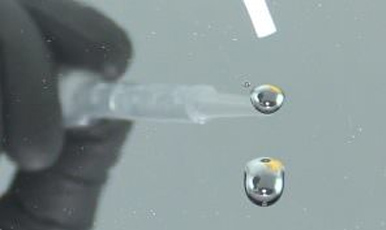

Contact angle measurement

Determination of the hydrophobicity

The following principle applies to contact angle measurement: The larger the contact angle, the greater the hydrophobicity. The greater the hydrophobicity, the easier it is for the water to run off and the drier the car is.

The stability of the waxes and chemical drying aids can be measured by means of a dynamic contact angle method. If the values remain consistently high, this shows that rain has very little impact on the seal.

Flocculation tests

Determination of service water quality

High-quality service water is crucial for a good car wash facility. The better the service water, the more stable the washing performance. Cloudy service water may react with the cleaning agents, which results in a deterioration in performance.

In addition, poor-quality service water can cause the entire system to become discoloured brown and can damage the external appearance of car wash facilities. There can also be a bad smell. Clear water does not have these negative properties. Use of a flocculant (polyaluminium salt) prevents the negative effects.

A test is carried out with polyaluminium salt in the development of a good flocculant The polyaluminium salt forms a stable flake in the service water which then usually sinks to the bottom, transporting suspended matter and unwanted material away. Crystal clear water remains.

External test institutions

NSF seal of quality

On the safe side with U.S. standard

Cleaners for gastronomy, canteen kitchens and the food-processing industry must meet especially strict requirements. One of the most important certifications is granted by the National Sanitary Foundation (NSF). The seal of quality of the American health protection organisation is recognised worldwide as the test standard for chemical substances in the sensitive food sector.

The chemical and toxicological safety of the recipe are examined as well as the instructions for use. This should rule out application errors.

Several of our products carry the coveted NSF seal of approval:

- Caramba all-purpose cleaner (profi line)

- Caramba stainless steel cleaner (profi line)

- Caramba high-performance silicone spray (profi line)

- Caramba high-performance grease with PTFE (profi line)

- Caramba high-performance multi-oil (profi line)

- Caramba I-Line AD-20 (industrial parts cleaning)

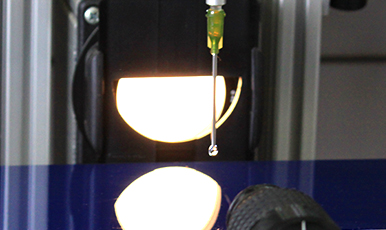

PTB test

Crucial test for solvents

Most solvent-based cleaners contain flammable substances. They must therefore be tested meticulously. For example, if an aerosol can is accidentally operated near hot surfaces or open flames, there must be no flashback of the spray jet. Continuous burning of residual amounts must also be ruled out.

We have such substances – e.g. the Caramba Brake Cleaner – tested by the Physikalisch-Technischen Bundesanstalt (PTB) in Braunschweig.

It is the most important German authority for this purpose. Its test certificate ensures optimal consumer safety. Flashback and continuous burning are ruled out with our products.

Test procedure for flammability:

- The product is sprayed on a metal bar that has a temperature of 825°C.

- When doing so, it is documented whether there is a flashback to the aerosol can.

- This is followed by a check of whether the sprayed residual amounts of product continue to burn.

- The spraying duration is increased incrementally.